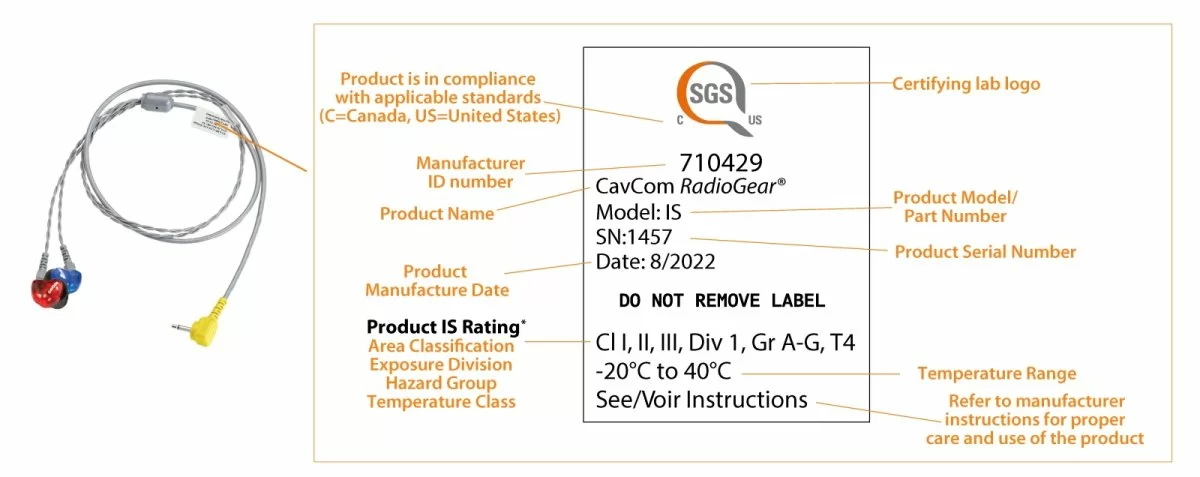

How to read an intrinsic safety label

Intrinsic safety certification is a highly involved process that measures the energy risk in a specific device according to each component. Manufacturers of products that are certified intrinsically safe must follow strict requirements for recordkeeping and documentation. Companies are inspected by the certifying body on a quarterly basis to ensure continued quality control and compliance. Manufacturers must also provide customers instructions for use of the product in hazardous locations. Lastly, products must be clearly marked with applicable intrinsic safety (IS) ratings.

*Product Intrinsic Safety Ratings

Area Classifications

- Class I: Explosive Gas Atmospheres (flammable gases, flammable and combustible liquid-produced vapors)

- Class II: Explosive Dust Atmospheres (combustible dust)

- Class III: Ignitable Fibers/Flyings (easily ignitable fibers or materials producing combustible flyings)

Exposure Division

- Division 1: Where ignitable concentrations of flammable gases, vapors/liquids, combustible dust, or combustible fibers/flyings can exist all of the time or some of the time under normal operating conditions

- Division 2: Where ignitable concentrations of flammable gases, vapors/liquids or combustible dust are not likely to exist under normal operating conditions; where easily ignitable fibers are stored or handled but not manufactured/used

Hazard Group

- Group A: Acetylene

- Group B: Hydrogen

- Group C: Ethylene

- Group D: Propane

- Group E: Metal dust (Div 1 only)

- Group F: coal (carbonaceous) dust

- Group G: non-conductive dust such as flour, grain, wood, plastic, etc.

Temperature Class/Range

-

Over a dozen temperature classifications; see "Temperature Range" for details on individual product specifications